The 300 and 200 series of regulators can be used in several different areas of application depending upon your requirements, with both single and dual stage regulator options, stainless steel,chrome plated brass barstock bodies or chrome plated forged brass bodies, chrome plated die cast zinc bonnets and stainless steel diaphragms.

Below you can find links to the various specification sheets, with key attributes listed:

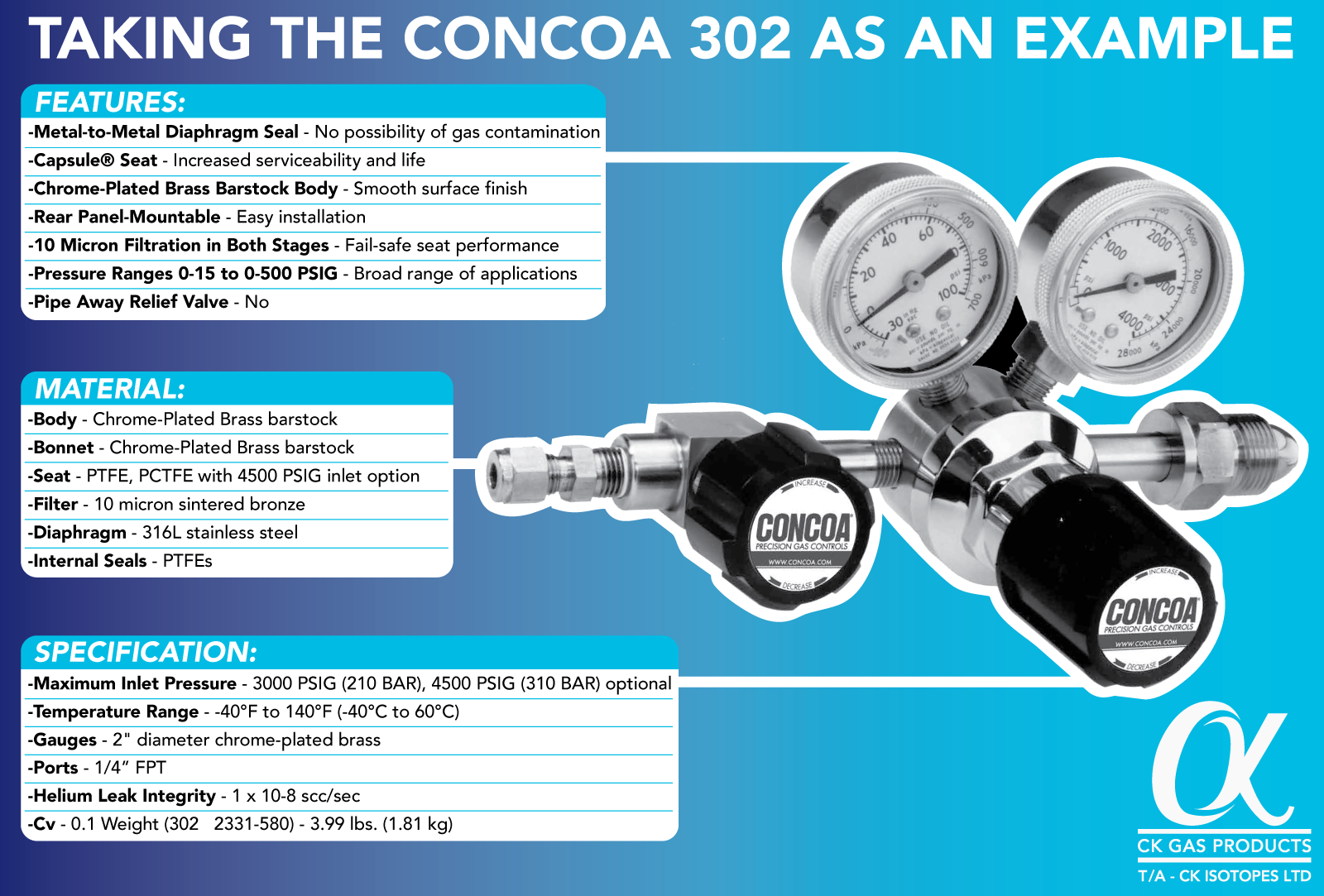

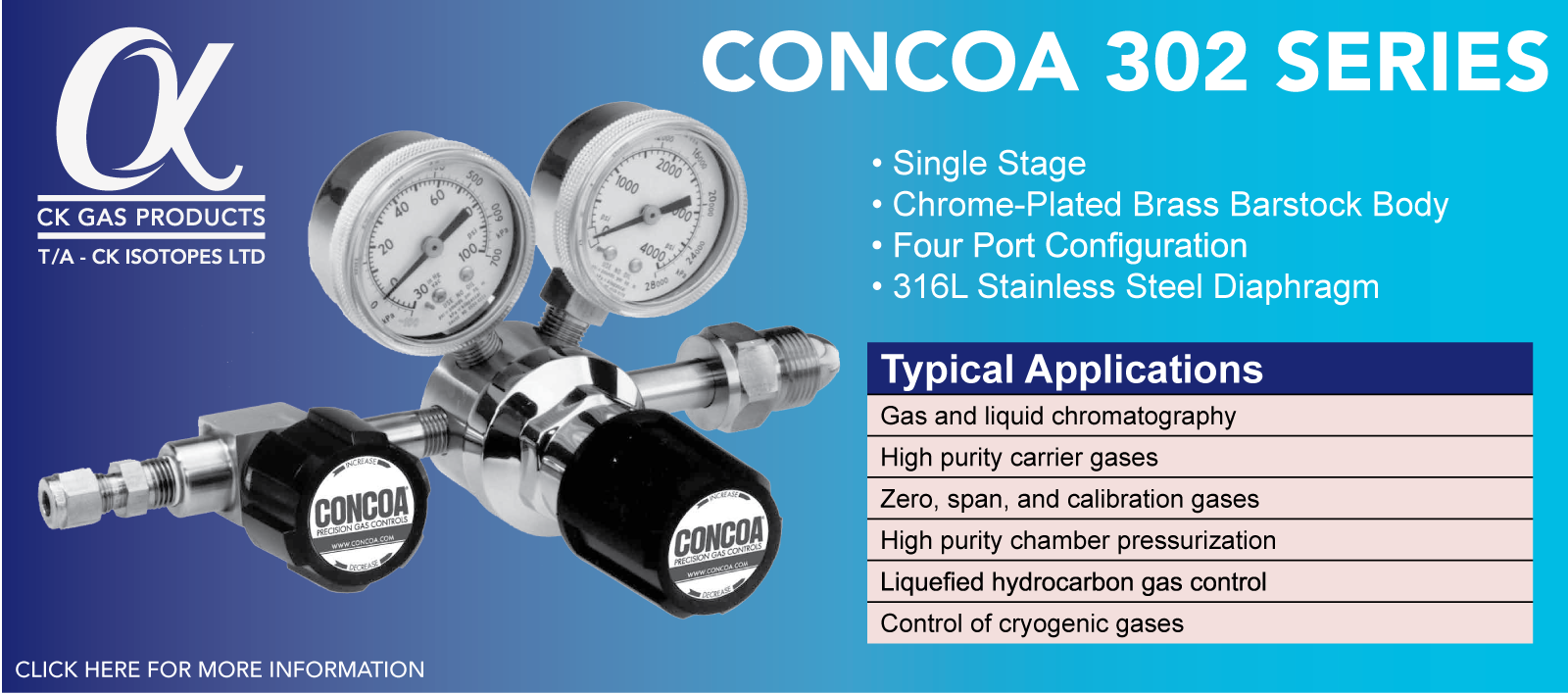

CONCOA 302 Regulator

The 302 series regulators are intended for primary pressure control of non-corrosive, high purity or liquified gases or for application where minor fluctuations in outlet pressure due to diminishing inlet supply can be tolerated.

302 Series Regulator with Flowcurve

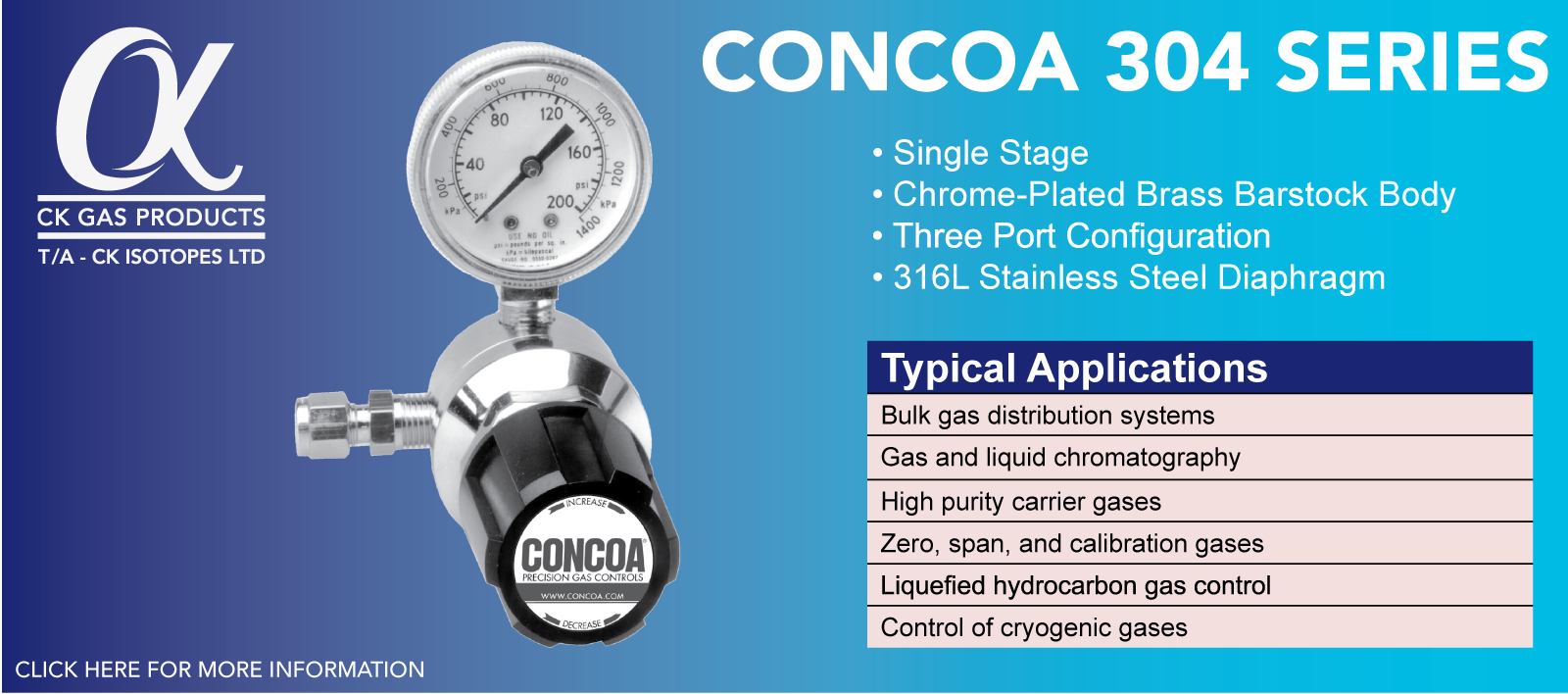

CONCOA 304 Regulator

The 304 Series regulators are intended for secondary pressure control of non-corrosive, high purity or liquefied gases or as point of use pressure control in high purity gas distribution systems.

304 Series Regulator with Flowcurve

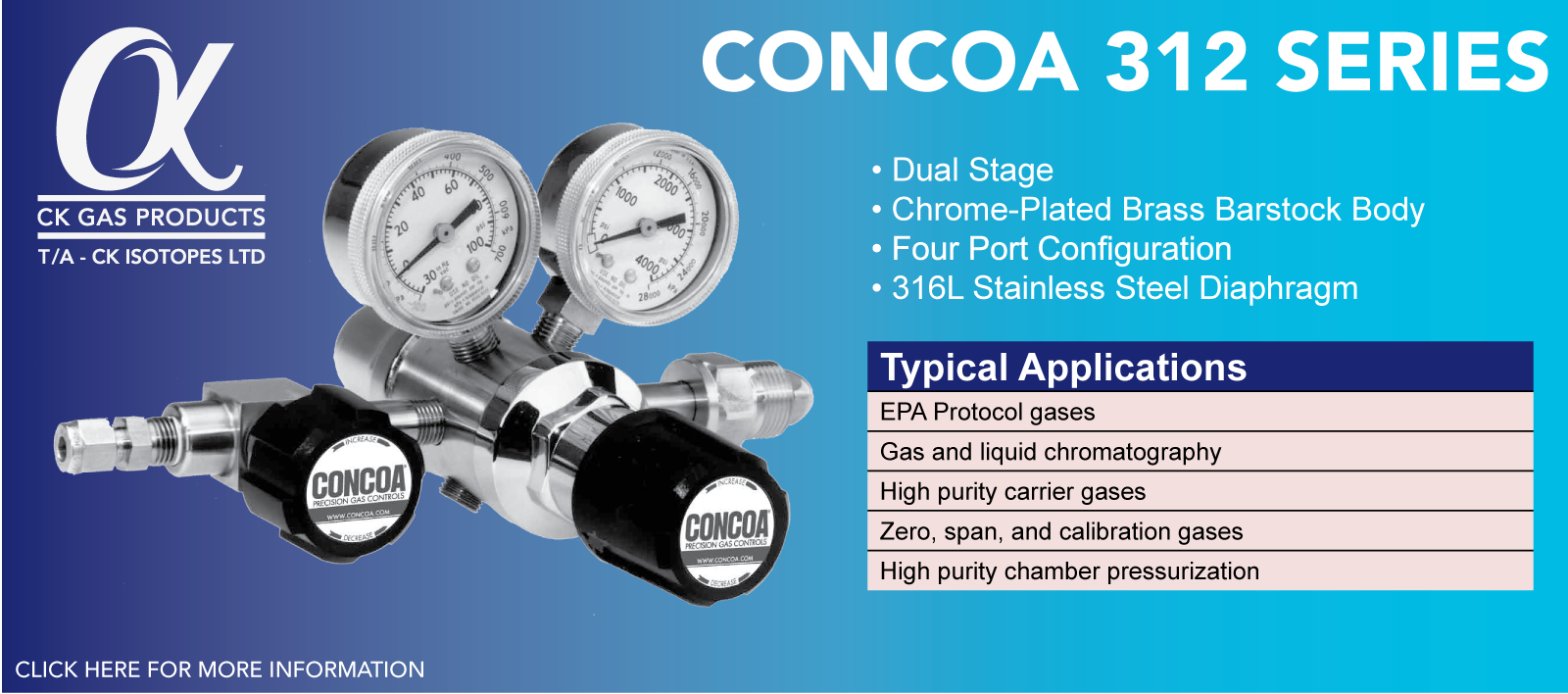

CONCOA 312 Regulator

The 312 Series regulators are intended for primary pressure control of non-corrosive, high purity or liquefied gases for applications requiring constant pressure control and delivery regardless of supply pressure variations.

312 Series Regulator with Flowcurve

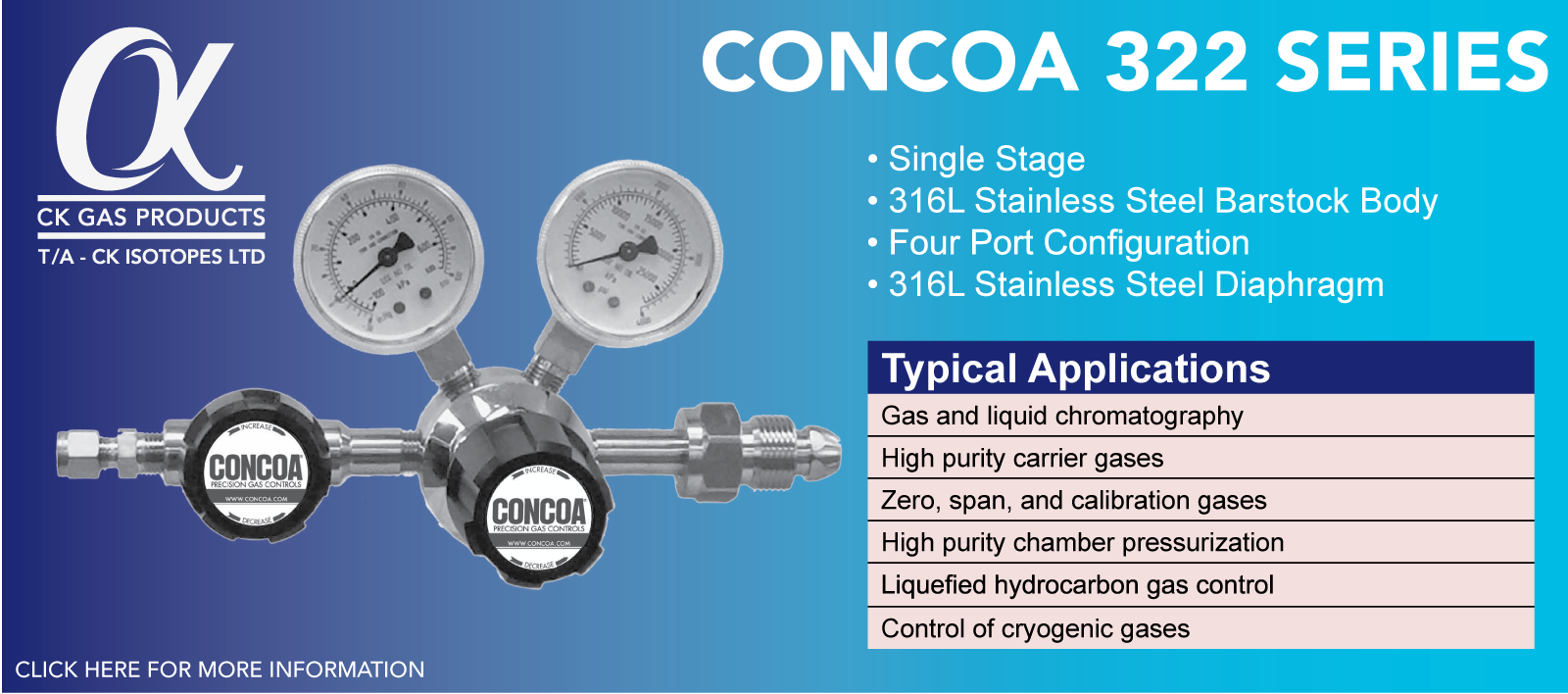

CONCOA 322 Regulator

The 322 Series regulators are intended for primary pressure control of ultra-high purity and corrosive gases in applications where minor fluctuations in outlet pressure due to diminishing inlet supply can be tolerated.

322 Series Regulator with Flowcurve

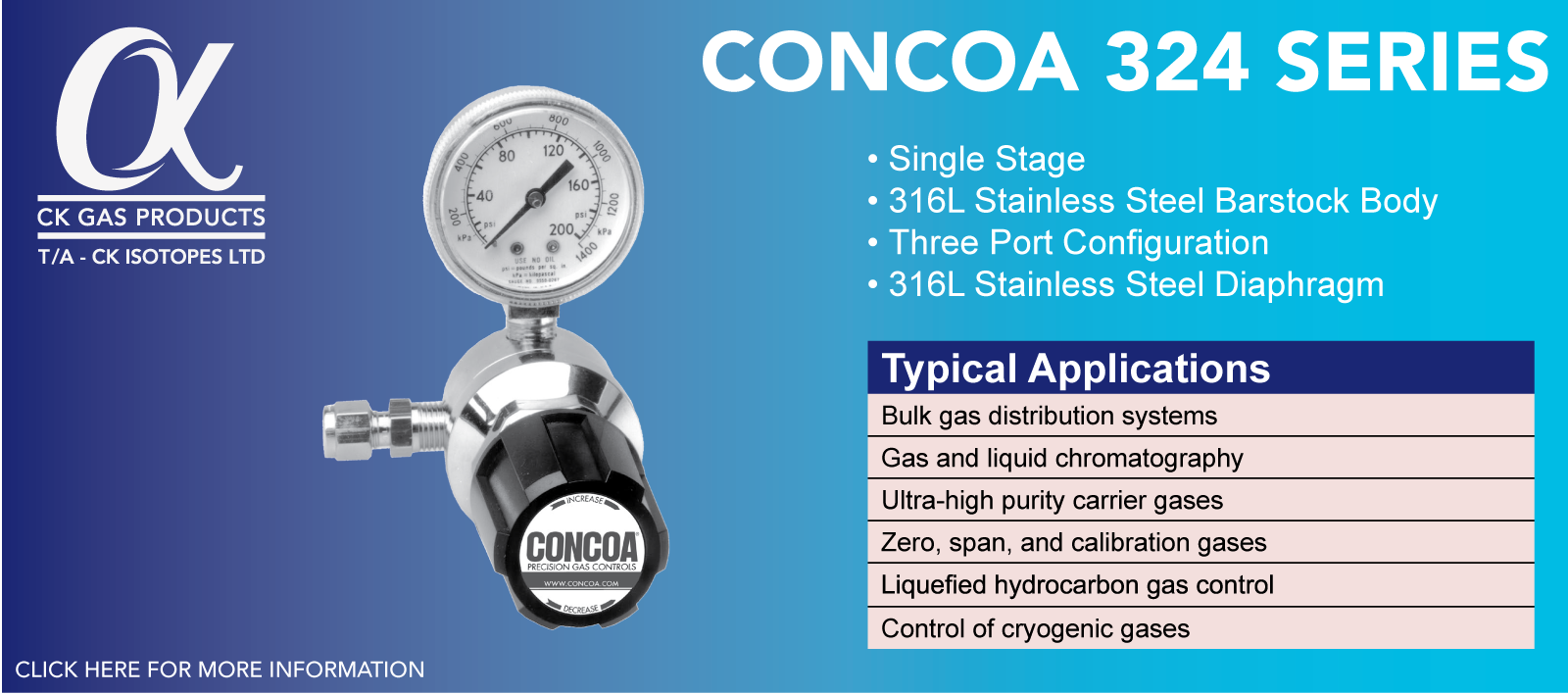

CONCOA 324 Regulator

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control and control of cryogenic gases.

324 Series Regulator with Flowcurve

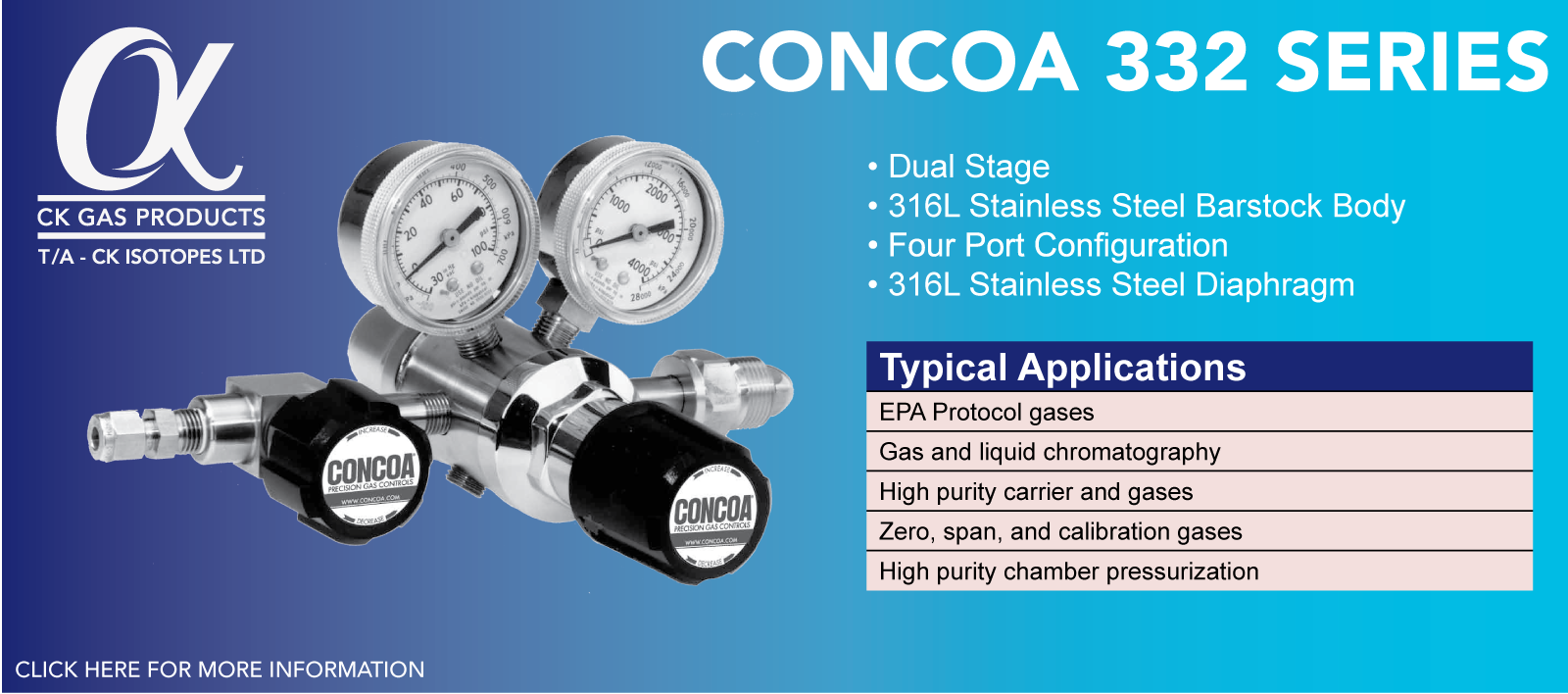

CONCOA 332 Regulator

The 332 Series regulators are intended for primary pressure control of ultra-high purity or corrosive gases for applications requiring constant pressure control and delivery regardless of supply pressure variations.

332 Series Regulator with Flowcurve

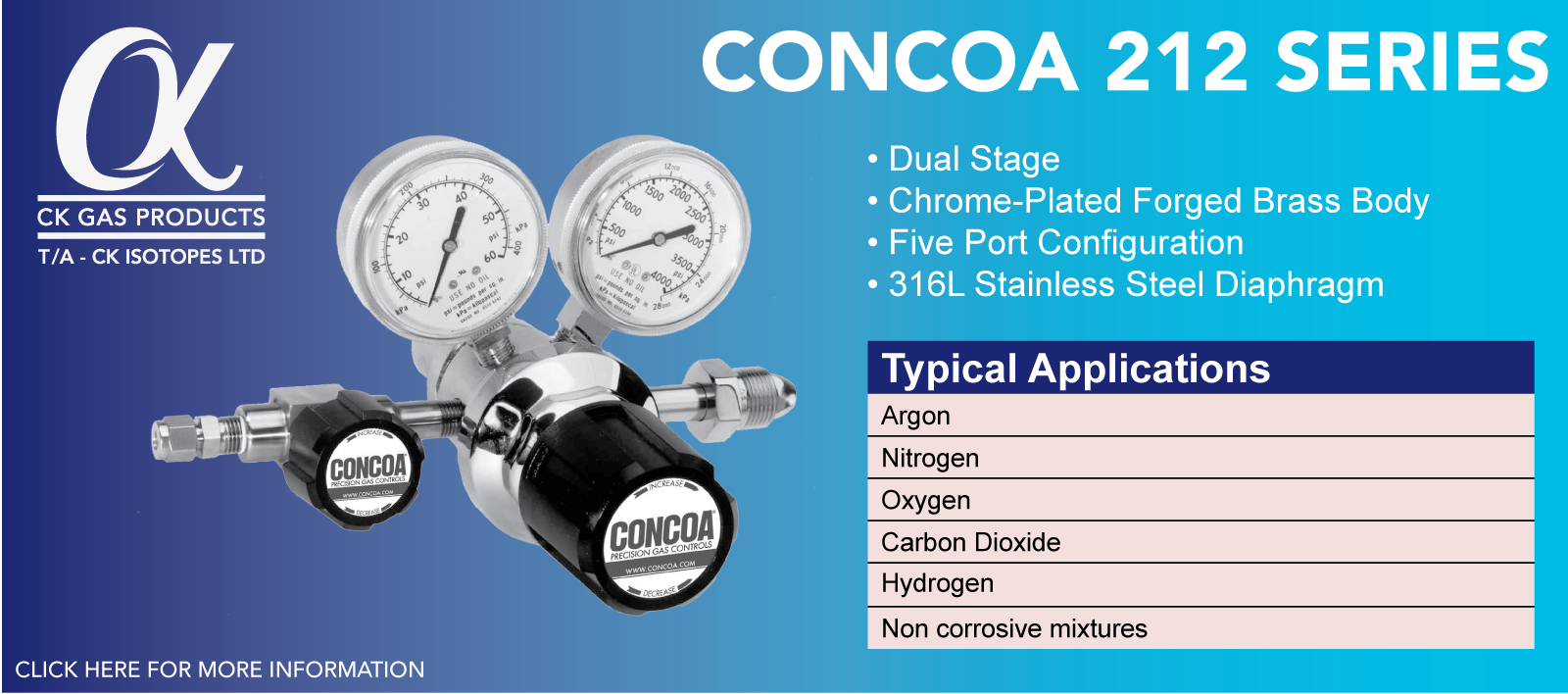

CONCOA 212 Regulator

Typical Applications – Gas supply purging, gas system charging, fuel gas supply control and calibration gas control.

212 Series Dual Stage Regulator with Flow Curves

SEE BELOW FOR MORE CONCOA ULTRA-HIGH PURITY REGULATORS IN THE RANGE:

CONCOA 307 Regulator

Key Features – Single Stage, Chrome Plated Brass Barstock Body, Four Port Configuration, Rear Inlet and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control and control of cryogenic gases.

307 Series Regulator with Flowcurve

CONCOA 332 Lecture Bottle Regulator

Key Features – Single Stage, Chrome Plated Brass Barstock Body, Four Port Configuration and 316L Stainless Steel Diaphragm.

Typical Applications – University Classrooms, University laboratories, Chemical Research and Pharmaceutical Manufacturing.

325 Series Regulator with Flowcurve

CONCOA 327 Regulator

Key Features – Single Stage, 316 Stainless Steel Barstock Body, Four Port Configuration, Rear Inlet and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control and control of cryogenic gases.

327 Series Regulator with Flowcurve

CONCOA 308 Regulator

Key Features – Single Stage, Chrome Plated Brass Barstock Body, Three Port Configuration, 316L Stainless Steel Diaphragm, Electrically Heated and NEMA 4 Housing.

Typical Applications – Chemical storage blanketing, anaerobic chambers, inert gas purging, atomic absorption oxidizer gas, semiconductor reactor furnace, inductively coupled plasma systems and pH control.

308 Series Regulator with Flowcurve

CONCOA 305 Regulator

Key Features – Single Stage, Chrome Plated Brass Barstock Body, 316L Stainless Steel Diaphragm and Custom Calibration.

Typical Applications – Blood gases, laser gases, medical research, pharmaceutical manufacturing and university laboratories.

305 Series Regulator with Flowcurve

CONCOA 315 Regulator

Key Features – Dual Stage, Chrome Plated Brass Barstock Body, 316L Stainless Steel Diaphragm and Custom Calibration.

Typical Applications – Blood gases, laser gases, medical research, pharmaceutical manufacturing and university laboratories.

315 Series Regulator with Flowcurve

CONCOA 202 Regulator

Key Features – Single Stage, Chrome Plated Forged Brass Body, 316L Stainless Steel Diaphragm and Five Port Configuration.

Typical Applications – Gas supply purging, gas system charging, fuel gas supply control, calibration gas control and atomic absorption acetylene.

202 Series Single Stage Regulator with Flow Curves

CONCOA 205 Regulator

Key Features – Single Stage, Chrome Plated Forged Brass Body, 316L Stainless Steel Diaphragm and Four Port Configuration.

Typical Applications – Point of use laboratory systems, gas supply purging, liquefied hydrocarbon gas control, control of cryogenic gases and bulk gas distribution systems.

205 Series Single Stage Regulator with Flow Curves

CONCOA 206 Liquid Cylinder Regulator

Key Features – Single Stage, Chrome Plated Forged Brass Body, 316L Stainless Steel Diaphragm and Four Port Configuration.

Typical Applications – Argon, Nitrogen, Oxygen, Carbon Dioxide and certain freons.

206 Series Single Stage Regulator with Flow Curves

Please contact us for a quote or if you have any questions.

Regulators – HIGH PURITY

Product Search

Got a Question?

For information please start your enquiry below: